![]()

Wommelgem – Ashes – Waregem . 23/03/2024

European food group “What’s Cooking?” and water treatment specialist Eco-Vision are joining forces to make water reuse a priority. The “water-as-a-service” project at the Wommelgem plant ensures maximum recovery of process water and works toward a closed water cycle. Result? A solid water savings of about one Olympic-sized pool every 10 hours.

“What’s Cooking?” is a European food group with 12 branches across Belgium, the Netherlands, France, Poland and the UK. In as many as 37 countries, “What’s Cooking?” easily conjures up delicious food on the table every day. Sustainable consumption is a priority for “What’s Cooking? The company sets the bar high. Maximum use of renewable resources, 100% recyclable or “recycle-ready” packaging by 2025 and running with renewable energy at all sites this year. These are just some of the sustainability goals to produce greener every day. Also of concern is the water-intensive nature of the food industry in general. It is crucial for the food industry to develop methods to minimize the impact on water resources.

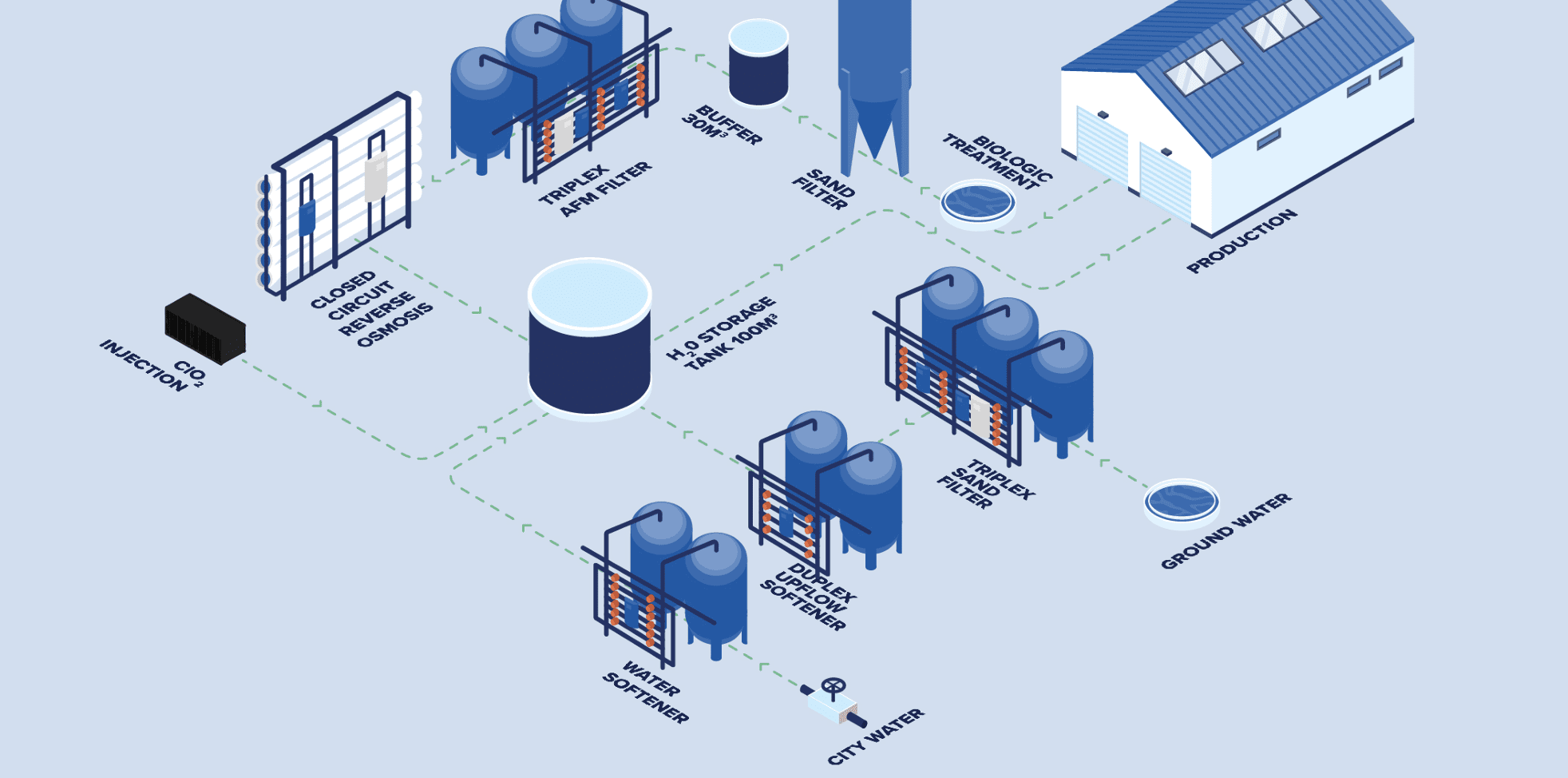

Together with Eco-Vision, “What’s Cooking?” is setting up a first project on process water recovery. Waste water from the production line in Wommelgem, also called eff luent, has been treated biologically for years. Without further treatment, the water is unusable and is discharged in accordance with environmental laws. However, by further purifying the water, reuse becomes possible. Eco-Vision, with facilities in As and Waregem, developed a CCRO (Closed Circuit Reverse Osmosis) solution in combination with glass filtration. After biological treatment, the effluent is recovered and continues its path through three glass filters. Glass is the ideal medium to collect residual biological fraction. The water is then passed through a reverse osmosis plant, type CCRO. In this process, water is forced under high pressure through a semi-permeable membrane to remove the last impurities. CCRO stands out thanks to the use of an internal closed-loop circuit.

The system is designed to minimize water loss. In traditional reverse osmosis systems, some saltwater that does not pass through the membrane is disposed of as wastewater. CCRO systems minimize wastewater. After treatment by the CCRO, the water receives a disinfectant chlorine dioxide injection. Thus, it can be reused as high-quality water in production. If more water is needed, a second system with groundwater steps in to replenish the reused water. Groundwater is treated to usable water through a sand filter and an upflow water softener. In case of water scarcity, there is also a third and final backup system with tap water. Tap water also flows through a water softener first. In the process, calcium is removed from the water to prevent limescale. The latter fallback is activated only in an emergency, but ensures business continuity.

Thanks to the technology and expertise of our partner Eco-Vision and the good project work of our engineer Tony Lanciers, we are now able to convert the wastewater from the production process into drinking water. Despite the drinking water quality achieved by the new plant, for now the water will only be used for cleaning our machines. So from now on, we put our treated wastewater to circular use to reduce our dependence on groundwater for purification purposes. If you think about the frequent and long periods of drought in recent years, we are certainly helping nature and the water table. The residual flow from the reuse plant enters Aquafin’s plants, which in turn further process the residual water.

The water reuse project is unique to “What’s Cooking?” and by extension the food industry. The discharge is reduced to salts and chlorides only. Moreover, CCRO is a relatively new development and the technique requires specific knowledge. The system provides much higher efficiency thanks to a single installation. Eco-Vision unburdens “What’s Cooking?” thanks to a “water-as-a-service” model. Here, Eco-Vision is responsible for the complete engineering, construction, operation and maintenance of the installation. “What’s Cooking?” pays a fixed amount per cubic meter of water recovered in exchange. Thanks to reuse, Eco-Vision and “What’s Cooking?” together manage to save 30 m3/hr. That is more or less equivalent to one Olympic-sized pool every 10 hours.